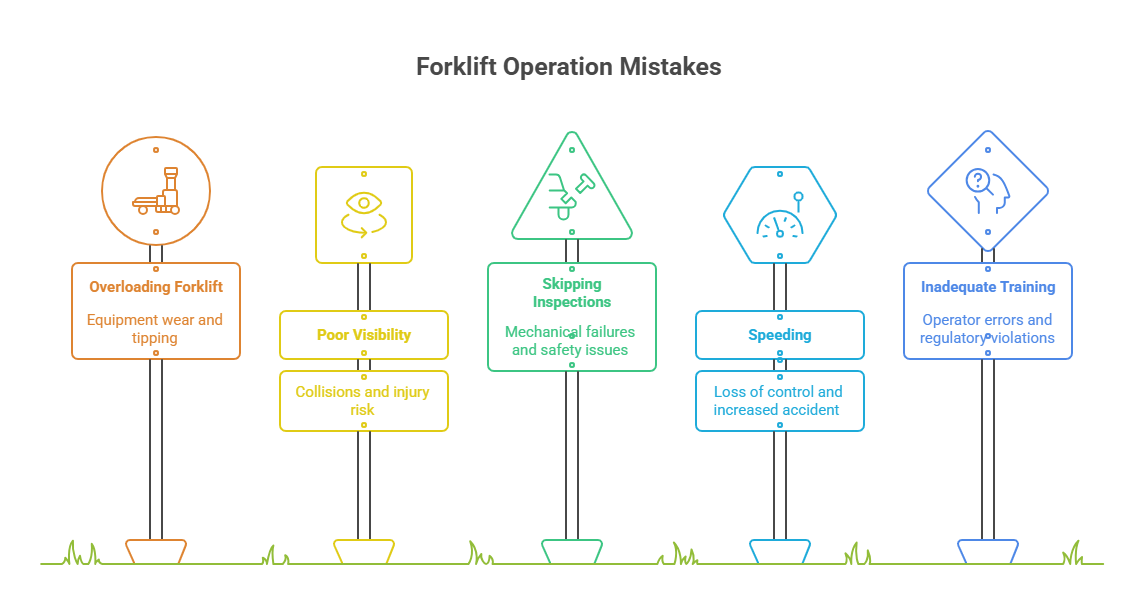

5 Common Mistakes to Avoid When Operating Heavy–Duty Forklifts

Heavy-duty forklifts are machines designed to lift and carry extremely heavy loads, often weighing several tons, in tough environments, including construction sites, warehouses, and manufacturing plants. They perform tasks that standard forklifts cannot handle and help keep operations efficient, safe, and running on time.

However, operating heavy forklifts requires more than just strength—it demands skill, awareness, and strict adherence to safety protocols. Mistakes during operation can lead to serious accidents, costly equipment damage, and unexpected downtime that disrupts productivity.

This article aims to highlight the five most common mistakes operators make when handling heavy-duty forklifts and how to avoid them to ensure safer, more efficient industrial operations.

Mistake #1 Overloading the Forklift

Exceeding a forklift’s rated load capacity is one of the most dangerous and costly mistakes in heavy-duty operations. It puts unnecessary strain on the equipment and increases the risk of tipping, especially when loads are raised or unevenly placed. Each forklift comes with a manufacturer-assigned load limit, clearly marked on the data plate, which must always be followed.

Operators should understand how load capacity is affected by the load center, typically 24 inches from the mast[1]. Placing loads too far forward, lifting unbalanced or unsecured items, or traveling with elevated forks can all shift the center of gravity and lead to instability.

To prevent this, it is essential to read the load chart carefully and ensure even weight distribution before lifting. Staying within the rated capacity is not just about protecting the machine—it’s also about protecting lives.

Mistake #2 Poor Visibility and Blind Spot Neglect

Operating a heavy forklift truck with limited visibility increases the risk of accidents, especially in busy or confined spaces. Tall or wide loads can block the operator’s forward view, hiding pedestrians, vehicles, or obstacles. Blind spots are also common around the rear, sides, and mast due to the machine’s structure and load placement.

One of the most common mistakes is driving forward with an obstructed view instead of reversing. Failing to use mirrors, cameras, or warning systems properly can further reduce awareness. Not checking surroundings before moving or underestimating the rear “tail swing” can also lead to collisions.

To reduce risks, operators should reverse when forward visibility is blocked, use spotters in complex areas, and regularly check mirrors and cameras.

Mistake #3 Skipping Pre-Operational Inspections

Neglecting daily pre-operational checks is a serious safety risk. These routine inspections are required by the Occupational Health and Safety Administration (OSHA) and are critical for identifying mechanical issues before they lead to equipment failure or accidents. Yet many operators skip them or rush through the process, often under pressure to start work quickly.

A proper inspection only takes a few minutes but covers key components that directly affect performance and safety. These include checking the brakes, tires, forks, mast assembly, hydraulics, and fluid levels. Warning signs like worn forks, low brake response, damaged tires, or leaking hydraulic fluid should never be ignored.

Operating a forklift with undetected faults can result in serious injury or equipment damage. Any machine with a visible defect should be taken out of service until properly repaired. Taking time for a thorough inspection helps prevent issues before they escalate.

Mistake #4 Speeding or Unsafe Driving Behavior

Rushing behind the wheel of a heavy-duty forklift puts everyone at risk. Sharp turns, sudden stops, or excessive speed can cause the machine to lose stability—especially when handling full loads or navigating tight spaces.

While OSHA does not set specific speed limits, industry recommendations advise keeping forklift speeds below 8 mph in general work areas and reducing to about 3 mph in high pedestrian zones. Forklifts can reach speeds up to 10 mph, but many workplaces impose stricter limits, often around 5 mph[2], when operating near people or other equipment to improve safety.

Operators should approach corners carefully, avoid abrupt movements, and always adjust speed to match site conditions. These habits help operators stay in control and prevent accidents that could halt work and threaten lives.

Mistake #5 Inadequate Operator Training

Untrained operators are a major risk factor—25% of all forklift accidents involve drivers who haven’t received proper training. Despite this, some job sites still allow uncertified personnel to operate equipment, putting both workers and operations at risk. OSHA requires all operators to complete classroom instruction, hands-on training, and an on-site evaluation before using a forklift.

Proper training should go beyond the basics. Operators need to understand the specific forklift model they’re using, including its limits, controls, and environment-specific hazards. For high-capacity forklifts, where loads and risks are greater, the need for certified instruction is even more critical.

Refresher training is also required, typically every three years or after an incident. Without it, operators may forget safe practices or fail to adapt to changes in equipment or worksite conditions. Investing in continuous training is a regulatory requirement, as well as it’s one of the most effective ways to reduce accidents and improve long-term site safety.

Conclusion

Poor visibility. Speeding in narrow aisles. Improper load handling. Skipping maintenance. Untrained operators. These aren’t minor mistakes—they are real risks that account for most forklift accidents and costly delays.

But safe operation goes beyond operator behavior. The forklift’s built-in safety features are equally crucial. At HELI, we are dedicated to providing high-quality heavy forklifts tailored for diverse warehousing needs.

Our heavy-duty forklifts are engineered with safety and ergonomics at their core. From enhanced visibility and intelligent control systems to operator-friendly cabin designs, every detail is meticulously crafted to minimize risks and boost operator confidence.

Looking to upgrade your fleet with smarter, safer equipment? Explore HELI’s full lineup or speak with our experts to find the best fit for your operation.

Reference

[1]. Understanding Load Capacities – Choosing the Right Forklift for Heavy Lifting. Available at: https://www.bencoindustrial.com/blog/common-warehouse-hazards-how-to-avoid-them.(Accessed on August 8, 2025)

[2]. Forklift Speed: Everything You Need to Know. https://www.conger.com/forklift-speed/. (Accessed on August 8, 2025)