AGV Automation: The Key to Faster, Safer Warehouse Operations

Designed for time-critical operations, AGVs streamline material flow with unmatched consistency. Their autonomous material handling ensures consistent, error-free movement of goods – exactly what today’s competitive warehouses require.

That’s why the AGV warehouse is in high demand. AGVs offer a powerful solution to many challenges. This article aims to help warehouse managers evaluate if such automation is the right choice for their facilities.

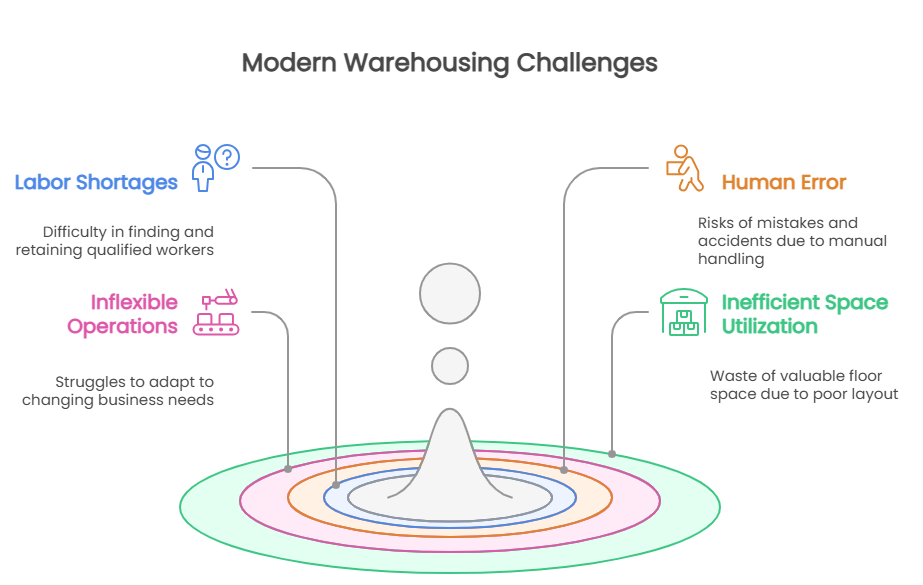

Challenges of Modern Warehousing

From inventory pileups to order fulfillment delays, warehouses are ground zero for supply chain breakdowns. The path forward? Implementing agile, automated systems designed for 21st-century logistics challenges. The following are the key challenges warehouses face:

Labor Shortages and Rising Costs

Finding and keeping qualified warehouse workers is increasingly difficult, especially as labor costs continue to rise across industries. Many warehouses struggle with high turnover rates, and the process of training new staff is expensive and time-consuming. On top of that, seasonal demand fluctuations add further complications.

Human Error and Safety Risks

Manual handling introduces risks of human error, where workers might misplace items or damage products. Besides, long work hours may lead to fatigue, which may increase mistakes and accidents. As a result, warehouses have high injury rates from lifting and equipment operations, with forklifts alone causing thousands of injuries annually, driving up worker compensation claims.

Inflexible Operations

Traditional warehouse setups struggle with changing business needs, as reconfiguring workflows requires significant downtime. This is not ideal, especially when peak seasons demand rapid scaling of operations. Manual processes cannot easily adapt to new product lines, and changes in order profiles create bottlenecks. Most warehouses lack the flexibility to adapt quickly.

Inefficient Space Utilization

Many warehouses waste valuable floor space due to poor layout design, which restricts movement and storage. Wide aisles required for manual forklifts further consume unnecessary space, while inconsistent stacking heights often leave vertical space underutilized. Improving space utilization has a direct and measurable impact on operational costs

How AGVs Solve These Challenges

AGVs address labor challenges by automating material movement tasks and operating 24/7 without breaks or shift changes — contributing to more predictable and stable labor costs. By taking over repetitive transportation duties, AGVs allow workers to focus on higher-value tasks.

Additionally, an AGV warehouse also eliminates the risks associated with human fatigue and reduces the need for overtime during busy periods. This AGV warehouse automation creates a more stable workforce model.

Safety improves dramatically with an AGV warehouse, as these machines have multiple safety sensors to prevent collisions and follow precise routes without taking shortcuts. Furthermore, the reduction in manual handling leads to fewer workplace injuries, while their consistent operation enhances inventory accuracy and contributes to a more controlled, safer working environment.

Safety improves significantly in an AGV-enabled warehouse, as these machines are equipped with multiple sensors to prevent collisions and follow precise, pre-defined routes without taking shortcuts.

AGV vs. Traditional Material Handling Equipment

AGVs offer significant advantages over traditional material handling equipment by combining automation with flexibility and adapting to different AGV warehouse environments. They can integrate with existing systems and workflows. Here’s a comparison between AGVs and traditional material-handling equipment:

Feature | AGVs | Traditional Material Handling Equipment |

Operation | Autonomous | Requires human operator |

Labor Cost | One-time investment plus maintenance | Ongoing operator wages and benefits |

Operating Hours | 24/7 operation possible | Limited by shifts and breaks |

Safety | Multiple sensors prevent accidents | Dependent on operator skill and attention |

Accuracy | Consistent performance | Varies with operator experience |

Space Requirements | Narrower aisles are possible | Wider aisles are needed for maneuverability |

Adaptability | Can be reprogrammed for new routes | Limited by operator training |

Data Collection | Automatic tracking and reporting | Manual tracking required |

Key Features of AGVs for Warehousing

AGVs have several key features that make them effective for warehouse operations. The diverse AGV warehouse capabilities deliver significant advantages, hence creating more efficient and responsive operations. The key highlights include:

Navigation Technologies

Modern AGVs use advanced navigation systems. Some follow magnetic tape or QR codes on floors, while others use laser guidance for precise positioning. The most advanced AGV warehouse models utilize natural feature navigation, allowing them to adapt to changing environments. These navigation systems enhance both the reliability and flexibility of AGV operations.

Customizable Solutions

AGVs come in many configurations to suit specific needs. Tow AGVs, for example, can pull multiple carts at once, while Fork AGVs handle palletized loads at different heights. Unit load AGVs, which are also very popular, move individual items or totes. Additionally, custom attachments handle specialized materials. With load capacities from a few pounds to several tons, this versatility makes AGVs suitable for various applications.

Scalability

AGV warehouse systems grow alongside your business. You can start with a few units and add more as needed. The same control system manages multiple vehicles, and new routes can be added without infrastructure changes. Additional AGVs integrate seamlessly into existing fleets, enabling a gradual approach that minimizes disruption to operations while allowing for phased investment in AGV automation.

Integration with Warehouse Management Systems (WMS)

AGVs connect directly to warehouse management software, hence creating seamless coordination of material flow. Tasks are automatically assigned to available vehicles, while real-time location data improves inventory tracking. The AGV warehouse management system optimizes routes for maximum efficiency, resulting in smoother workflows and better resource utilization.

HELI: Reliable Partner for AGV Solutions

With over six decades of experience in material handling, Anhui Heli has grown into a global leader in industrial vehicles—ranked among the world’s top 7. Our AGV solutions are engineered to meet the real demands of modern warehouses, improving efficiency, safety, and scalability. With established brand centers in France, Thailand, the U.S., Dubai, and more, Heli delivers reliable automation backed by global support.

Our advanced AGV options include the 1.0t Omni-directional Counterbalanced AGV and 1.5-1.6t i-Series Fork Over Stacker AGV. These machines handle diverse material movement tasks and excel in different warehouse environments. Some key features of our AGV lineup include:

- Omnidirectional movement for flexible operation in tight spaces

- No load reduction at heights up to 3m with full capacity

- Large-capacity lithium batteries with extended service life

- Side-placed automatic charging with integrated chargers

- Multiple safety protections for intelligent and secure operation

- Maintenance-free AC steering motors for reliability

- Compact structure that minimizes required passage space

HELI has proven successful in real-world applications. Jiangsu Kelas Environmental Protection Technology Co., Ltd. partnered with us for their factory automation. They needed a flexible, intelligent AGV logistics system, and our solutions met their demands with independent navigation and route planning capabilities.

In response, HELI has deliverd AGV solutions that features flexible route planning, 24/7 multi-vehicle collaboration, and safe navigation in mixed-traffic and semi-outdoor areas. Integrated with intelligent warehouse management and AI vision systems, our solutions enable full-process automation—reducing costs and significantly improving operational efficiency.

Conclusion

AGVs transform warehouse operations through automation and intelligent systems. They address labor shortages and safety challenges while also improving space utilization and operational flexibility. By streamlining workflows, AGV technology creates more predictable and efficient operations.

At Anhui Heli, we offer reliable AGV warehouse solutions backed by decades of experience. Contact us to discuss how our solutions can transform your AGV material handling processes. Let’s build a more efficient, safer warehouse together.