Logistics automation systems are integrated systems that utilize advanced technology and equipment to optimize logistics processes. It is critical in the modern supply chain to improve efficiency, reduce costs, and enhance accuracy.

AGVs (automated-guided vehicles) and RGVs (rail-guided vehicles) are two commonly used modes of automated transportation. AGVs are flexible for complex environments, while RGVs are stable and suitable for fixed routes.

This article aims to help readers choose the best logistics automation system between AGV and RGV for their operations.

What Is an AGV?

AGV automated-guided vehicles are intelligent mobile robots that can travel autonomously on a preset path and complete transportation tasks. It determines the driving route through laser navigation, magnetic stripe navigation, or visual navigation without the need for manual driving.

The main functions of AGV include efficient material handling, cargo transportation, assembly line feeding, and order picking. It can automatically identify the location of goods and accurately transport them to the designated place, improving logistics efficiency and reducing manual errors. Beyond efficient warehousing management, AGVs are also equipped with automatic charging functions, which can realize 24-hour uninterrupted operation.

From navigating vast e-commerce warehouses to delivering components on automotive lines and transporting sterile supplies in hospitals, AGVs are at the heart of automated logistics— showcasing their flexibility across complex and varied environments.

What Is an RGV?

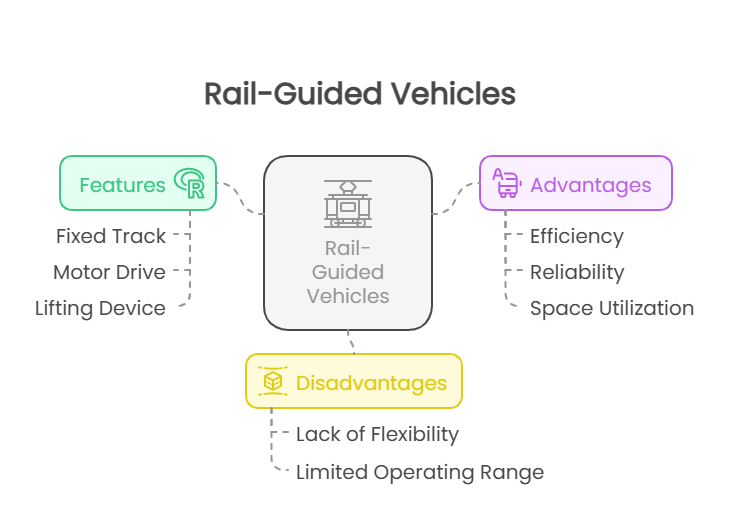

Rail-guided vehicles (RGVs) are automated transportation equipment running on a fixed track, which is commonly used in automated storage and retrieval systems.

An RGV is guided by the track installed on the ground and relies on the motor drive to move along the track in a straight line or curve, which can realize the rapid handling and storage of goods.

Some of them are equipped with a lifting device capable of lifting goods from the floor to a specified height on a shelf or removing goods from a shelf and delivering them to a specified location.

In structured environments like high-density storage warehouses, RGVs stand out for their efficiency and reliability. Running on fixed tracks with high positioning accuracy, they make excellent use of limited space. Their fast operation speeds and low failure rates help streamline material handling while ensuring stable, uninterrupted performance.

However, RGVs lack flexibility — once the tracks are laid, the path is fixed and difficult to modify. They also involve high initial installation costs and have a limited operating range, constrained by the track length. Unlike AGVs, RGVs are less adaptable to complex or dynamic environments.

AGV vs RGV: Key Differences

Features | AGV | RGV |

Flexibility | High.

| Low.

|

Scalability | High.

| Low.

|

Layout requirements | Low.

| High.

|

Cost & maintenance |

|

|

Suitable environments | Complex and dynamic environments, flexible production lines, and e-commerce warehouses. | Fixed paths, stable environments, large-scale warehouses, automated storage and retrieval systems (AS/RS). |

Why AGVs Are Gaining Popularity

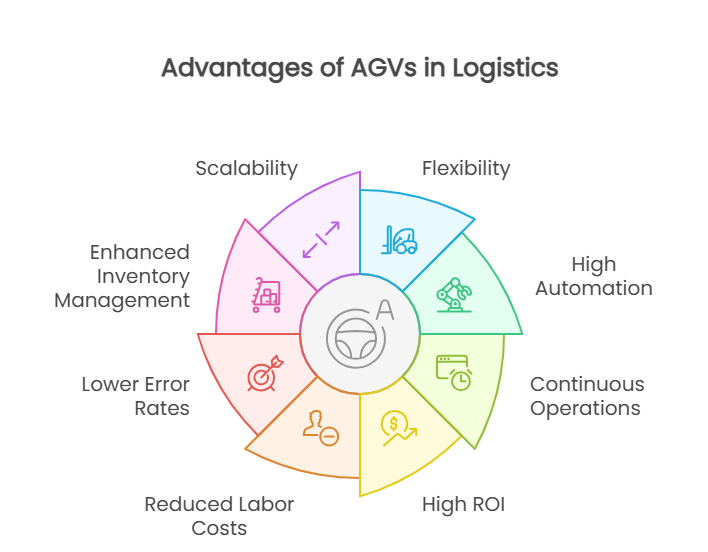

While AGVs and RGVs have their merits for logistic automation systems, AGVs are increasingly preferred. Advantages of AGVs, such as flexibility, high automation, and continuous operations, give an edge to those in need of fast-paced logistics.

Beyond outstanding performance, AGVs also feature a high return on investment. With AGV systems, business owners can reduce labor costs, lower error rates, and enhance inventory management. Besides, they require less infrastructure expenses as there is no need for complex navigation systems, which helps decrease both the initial investment and maintenance costs. Furthermore, AGV systems are highly scalable and easily adaptable to business expansion and changes in production processes.

Therefore, with these features, AGVs have broad application value across third-party logistics (3PL), e-commerce, and manufacturing for their ability to streamline logistics and boost operational efficiency. From handling high-frequency orders in e-commerce to moving materials on production lines, AGVs help businesses stay fast, flexible, and competitive.

HELI AGV Solutions for Smart Logistics

As AGVs become an integral part of logistics automation systems, partnering with a trusted and experienced provider is key to long-term success. Among the top 10 global forklift manufacturers, HELI is bound to deliver robust AGV forklifts that suit your needs.

With decades of expertise in industrial vehicles, HELI’s AGVs are designed for diverse applications — from unmanned warehouses and intelligent sorting to flexible production line transfers.

Integrated with WMS and production systems, they support real-time task execution and seamless automation. From stacking to heavy-duty models, each AGV is engineered for stability, safety, and high performance.

HELI’s end-to-end service — from needs analysis to system integration — ensures every solution fits your specific scenario, empowering businesses to streamline operations and embrace intelligent, unmanned logistics.

Partner with HELI for Greater Automation

Compared to RGVs, AGVs offer greater flexibility, scalability, and cost-efficiency, serving as a smarter fit for building a dynamic, future-ready logistics automation system.

Ready to upgrade your logistics with intelligent automation? Partner with HELI — your trusted AGV manufacturer—for tailored, high-performance solutions that move your business forward.