How to Upgrade Your Forklift Fleet to Lithium Batteries Safely

Imagine a warehouse where forklifts run longer, charge faster, and create a safer, cleaner workspace. That’s the promise lithium batteries bring to modern fleets. For companies still relying on traditional lead-acid power, the question isn’t if they should upgrade, but when and how to do it without risk.

Choosing the right time and approach can unlock higher productivity, lower operating costs, and a more sustainable future for your business. In this blog, we’ll explore the key steps to upgrading your forklift fleet to lithium batteries safely and successfully.

Why Upgrade to Lithium Batteries?

Switching to lithium batteries brings clear advantages for businesses that rely on forklifts every day. Here are the three biggest reasons to consider the upgrade:

Lower Total Cost of Ownership

Lithium batteries may cost more upfront, but their longer lifespan and minimal maintenance quickly balance the scales. A single lithium unit can last two to three times longer than a lead-acid battery and eliminates weekly watering or monthly downtime for servicing.

Many multi-shift operations recover their investment in as little as two to three years, while also saving valuable floor space by removing the need for large charging rooms.

Environmental and Emission Benefits

Unlike lead-acid batteries, lithium batteries are sealed and free from harmful acid spills or gas emissions, making workplaces safer and cleaner. Their extended lifecycle also means fewer replacements and less waste over time, reducing overall environmental impact.

For companies aiming to meet stricter sustainability and compliance standards, lithium is a much more future-ready choice.

Improved Operational Efficiency

Faster charging and opportunity charging during short breaks keep forklifts running longer and reduce downtime. Lithium batteries also deliver consistent power output until fully discharged, avoiding the sluggish performance common with lead-acid.

Even in cold storage environments, they retain nearly full capacity, ensuring reliable productivity in challenging conditions.

Assessing Your Existing Fleet

Before making the switch, it’s important to take a close look at your current fleet. A proper assessment ensures you choose the right batteries, avoid unexpected issues, and get the best return on your investment. Here are the key areas to focus on:

Check Forklift Compatibility

Start by confirming whether your forklifts can physically and electrically support lithium batteries. Pay attention to details such as voltage, current, and the size of the battery compartment. In some cases, modifications may be needed to fit the new units properly. Getting this step right prevents costly mismatches and ensures a safe, reliable upgrade.

Select the Right Battery and BMS

Not all lithium batteries are created equal. Choosing a model with the proper capacity and a high-quality Battery Management System (BMS) is critical. The BMS actively monitors temperature, charge levels, and voltage to protect both the battery and the forklift. By matching the right lithium battery to your forklift fleet’s specific needs, you’ll extend lifespan and maintain safe, consistent performance.

Evaluate Operational Requirements

Every fleet operates differently, so it’s essential to factor in workload, shift length, and usage intensity. For example, a multi-shift warehouse will need batteries with faster charging and longer runtime, while operations in cold storage require batteries that maintain capacity at low temperatures. By aligning your battery choice with real-world conditions, you can maximize uptime and efficiency across your fleet.

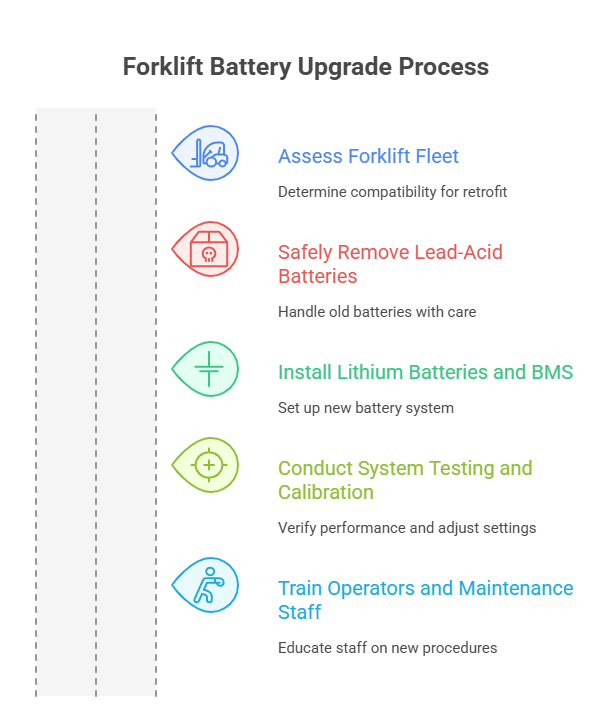

Step-by-Step Conversion Process

Once you’ve assessed your forklift fleet, the next stage is putting the upgrade into action. A structured approach will make the transition smoother and safer for everyone involved. Here are the key steps:

Step 1: Safely Remove Lead-Acid Batteries

Not all forklifts are suitable for retrofit, so first confirm compatibility before removing old units. Lead-acid batteries can be heavy, corrosive, and hazardous if mishandled. Following proper disposal and recycling procedures is essential to protect both workers and the environment.

Step 2: Install Lithium Batteries and BMS

After preparing the forklift, install the lithium battery along with its battery management system. Correct installation sets the foundation for long-term reliability.

Step 3: Conduct System Testing and Calibration

Once installed, the system should be tested to verify safe operation and consistent power output. Calibration may also be needed to adjust counterbalancing or update the forklift’s data plate, since lithium batteries are lighter than lead-acid ones. This step ensures the equipment performs as intended before returning to service.

Step 4: Train Operators and Maintenance Staff

A successful conversion goes beyond hardware. Operators and technicians need to understand new charging procedures, safety protocols, and daily checks. Training helps prevent misuse, maximizes battery life, and creates confidence in handling the upgraded forklift fleet.

Potential Challenges and Solutions

Upgrading to lithium batteries for your forklift fleet offers great benefits, but it’s important to anticipate potential hurdles and plan ahead.

High Initial Investment

Lithium batteries cost more upfront than lead-acid options, which can concern budget planning. However, their longer lifespan, faster charging, and low maintenance quickly offset the investment. Multi-shift operations often see payback within two to three years, and an ROI calculator can help quantify the long-term savings.

Safety Risks

While lithium batteries are generally safe, improper handling, overcharging, or short circuits could pose hazards. Installing a reliable BMS, conducting daily inspections, and training operators on proper use ensure both staff and equipment stay protected.

Updating Charging Systems

Existing lead-acid charging infrastructure may not meet lithium requirements. Moving to decentralized fast-charging stations near operational zones enables “opportunity charging,” reduces downtime, and keeps productivity high.

Supplier Reliability

Choosing an inexperienced vendor can lead to maintenance problems or unexpected downtime. Partnering with reputable suppliers offering strong warranties and responsive technical support ensures a smooth, worry-free transition.

HELI Lithium-ion Forklifts for Your Fleet

If retrofitting your existing forklifts with lithium batteries feels complicated, or if some units aren’t compatible, another effective solution is to integrate purpose-built lithium-ion forklifts into your fleet. HELI offers a range of lithium-powered forklifts designed to deliver safe, efficient, and low-maintenance performance right out of the box.

HELI lithium-ion forklifts, with load capacities from 0.8t to 10t, are ideal for a variety of industries, including warehouses, logistics centers, manufacturing, and cold storage. They provide fast charging, long-lasting performance, and consistent power throughout the workday, while their lighter, more maneuverable design reduces maintenance and downtime, helping your fleet operate safer, more efficiently, and cost-effectively.

Conclusion

By assessing your existing fleet, selecting the right lithium solution, and following a careful conversion process, or choosing purpose-built lithium-ion forklifts, you can achieve a smooth and cost-effective transition.

Ready to upgrade? Explore HELI today and request a consultation for your forklift fleet.