How Do Anhui Heli Forklifts Ensure Hazardous Material Handling?

In the chemical and manufacturing industries, hazardous materials handling is an extremely critical operation, the safety of which is directly related to the lives of personnel, equipment safety, and environmental stability. Even minor negligence can lead to serious accidents and irreversible damage.

Therefore, ensuring the safety of dangerous goods loading and unloading remains a key concern throughout the industry. This article will show how HELI forklift trucks, with their excellent performance, provide safe and reliable solutions for hazardous material handling.

What is Considered Hazardous?

Hazardous materials are substances with flammable, toxic, and corrosive properties.

- Flammable materials, such as gasoline and alcohol, are highly combustible when exposed to fire.

- Toxic substances, such as cyanide and mercury, can result inserious injury to the human body by inhalation or contact.

- Corrosive materials, such as sulphuric acid and sodium hydroxide, can chemically erode skin and equipment.

These dangerous goods must be stored and transported in strict compliance with safety norms to prevent accidents such as leakage, burning, or poisoning.

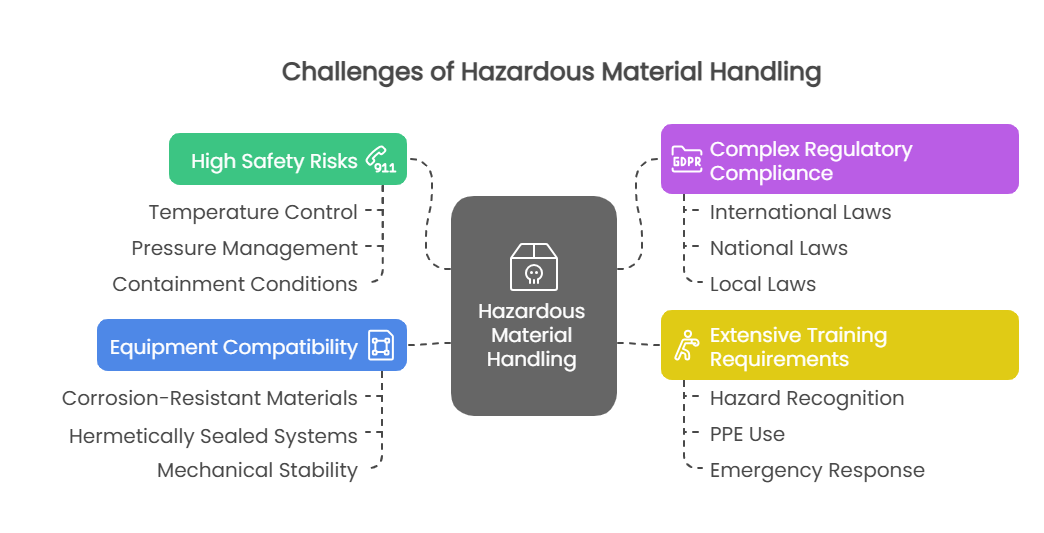

Challenges of Hazardous Material Handling

Once we know what we’re dealing with, the next question is: how do we manage it without putting people or the environment at risk? In practice, managing these hazardous materials comes with its own set of challenges.

High safety risks

Handling hazardous materials often requires strict control of temperature, pressure, and containment conditions. Certain chemicals may become unstable when exposed to moisture, oxygen, or incompatible substances, increasing the likelihood of combustion or chemical reactions. Managing these risks demands advanced monitoring systems, preventive maintenance of storage facilities, and material-specific handling procedures.

Complex regulatory compliance

Hazardous materials are regulated by a patchwork of international, national, and local laws, including standards from agencies such as OSHA, DOT (US), and REACH (EU).

These regulations govern every aspect of material handling—from classification and labeling to transportation and disposal.

Keeping up with regulatory updates and ensuring full compliance can be resource-intensive and requires dedicated compliance teams.

Extensive training requirements

Personnel involved in the safe handling of chemicals in the workplace must undergo rigorous and recurring training. This includes hazard recognition, use of PPE, emergency response procedures, and familiarity with material safety data sheets (SDS).

Inadequate training remains one of the leading causes of hazmat-related workplace incidents, making workforce education a top operational priority.

Equipment compatibility

Hazardous materials are often highly corrosive or toxic, requiring the use of corrosion-resistant materials and hermetically sealed systems. Equipment must also maintain mechanical stability and operational reliability under extreme or variable environmental conditions. Inadequate compatibility can result in leaks, structural failure, or serious safety risks to personnel.

Safety Features of HELI Forklifts for Hazardous Environments

In response to the challenges of hazardous material handling, HELI, a leading forklift manufacturer, has developed specialized forklifts designed specifically for the chemistry industry, combining advanced safety features, durability, and operational efficiency.

Integrated multi-vehicle logistics solutions

HELI offers an integrated logistics solution that enables the coordinated operation of multiple vehicle types, including forklifts, pallet trucks, stackers, and tow tractors. This multi-vehicle synergy ensures smoother task transitions and greater flexibility in adapting to diverse handling scenarios.

High-lift precision with enhanced safety

Designed for high-rack storage environments common in chemical warehouses, HELI’s electric stacker trucks offer a maximum lifting height of up to 12.5 meters.

Equipped with a lifting height display and reinforced masts, they enable precise control during high-position operations.

The compact turning radius and EPS power steering system further enhance maneuverability, ensuring stable and secure handling even in tight, elevated spaces.

Ergonomic design for operator comfort

HELI forklifts feature wide-view masts, flexible steering, and ratchet handbrakes—all tailored to reduce fatigue in high-frequency handling.

The cast steering axle enables smoother turning, while the overall ergonomic layout improves comfort during long shifts.

Eco-friendly and energy-efficient operation

HELI’s lightweight design and efficient transmission minimize energy use and support all-day operations on a single charge — making green handling possible even in sensitive environments.

Application-Specific Solutions for the Chemical Industry

Building on these capabilities, HELI offers dedicated industrial vehicle solutions specifically designed to meet the demands of hazardous material environments. Here are two standout models that make a difference.

12-18t Li-ion Forklift Truck

Built for heavy-duty hazardous environments, this high-voltage (600V) lithium forklift delivers efficient power with minimal energy loss — ideal for chemical plants or warehouses needing clean, reliable lifting.

Fast charging (up to 120 kW) gets you from 10% to 90% in just 90 minutes, keeping downtime low. Centralized cab control and intelligent gearbox ensure smooth handling and operator comfort in complex, high-risk operations.

1.5-3t Pallet Truck AGV

Designed for precise, automated material transfer in tight spaces, this compact AGV excels at moving goods between warehouses and production lines. The familiarized design leverages advanced technology for easy operation and integration. Additionally, its servo control system ensures high accuracy, minimizing errors in hazardous or busy chemical plants.

Choose HELI for Safer Material Handling

In handling and storage of chemicals, precision, safety, and reliability are non-negotiable. To meet these demands, specialized equipment designed for challenging environments is essential.

Whether you’re managing high-risk chemical logistics or complex plant workflows, HELI’s specialized forklifts empower your team to work confidently and efficiently.

Partner with HELI and take your hazardous material handling to the next level. Reach out to our experts today.