The Rise of Electric Forklifts: Sustainable Solutions for Material Handling

Forklifts have long been essential to material handling, but a powerful shift is underway. Once dominated by internal combustion models, the market is now rapidly tilting toward electric alternatives.

Electric forklifts already account for nearly 70% of global forklift shipments, according to Interact Analysis[1], and the market is projected to more than double, from $60.9 billion in 2025 to $154.1 billion by 2032[2], as forecasted by Fairfield Market Research.

This rapid growth underscores a structural shift toward electrification as the dominant force in material handling. In this article, we explore the factors fueling this transition and how electric forklifts are reshaping operations across industries.

What Are Electric Forklifts?

Electric forklifts are material handling vehicles powered by rechargeable batteries rather than internal combustion engines. Unlike diesel or LPG models, they generate zero emissions during operation, making them a preferred choice for indoor and environmentally sensitive applications.

At their core, electric forklifts consist of three main components: an electric motor that drives the vehicle and lifts loads, an onboard battery that stores energy, and a charging system to replenish power. This clean, quiet, and low-maintenance design is a key driver of their growing popularity.

Environmental Benefits of Electric Forklifts

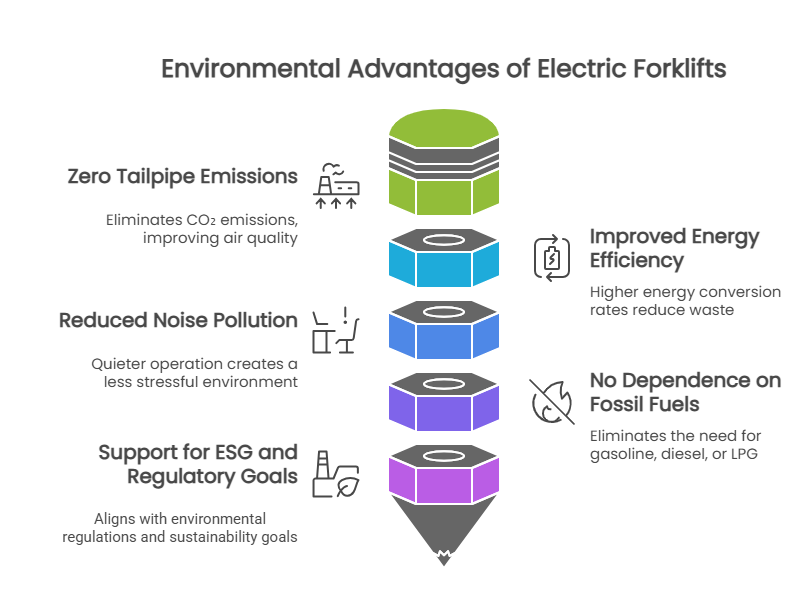

As businesses are under greater pressure to reduce their carbon footprint and satisfy sustainability goals, electric forklifts have emerged as a key solution in environmentally responsible material handling. Their adoption brings multiple ecological and operational advantages:

Zero Tailpipe Emissions

Electric forklifts generate no tailpipe emissions during operation, cutting up to 5 tonnes of CO₂ per unit each year. For indoor material handling environments like warehouses and distribution centers, this translates to cleaner air and safer working conditions.

Improved Energy Efficiency

Electric forklifts convert a greater share of input energy into usable power compared to internal combustion models. This efficiency is supported by advanced battery technologies, with lead-acid systems typically reaching around 80% energy retention, while lithium-ion designs achieve up to 95%. Higher energy retention reduces waste and operating costs in material handling applications.

Reduced Noise Pollution

Electric forklifts operate more quietly than diesel or LPG models. This reduces workplace noise, creating a less stressful environment and lowering employees’ risk of hearing damage. It also helps meet noise regulations and minimizes environmental noise, especially important in sensitive areas.

No Dependence on Fossil Fuels

Battery-operated forklifts eliminate the need for gasoline, diesel, or LPG, reducing reliance on fossil fuels. This also removes the hazards of fuel storage, such as fire risk, spills, and regulatory compliance, as well as the ongoing costs of purchasing and transporting fuel.

Support for ESG and Regulatory Goals

Across North America, Europe, and Asia, stringent environmental regulations are accelerating the move toward zero-emission forklifts. In California, for instance, the Zero-Emission Forklift Fleet Requirements Regulation compels the replacement of Large Spark-Ignition forklifts with zero-emission alternatives to cut emissions[3].

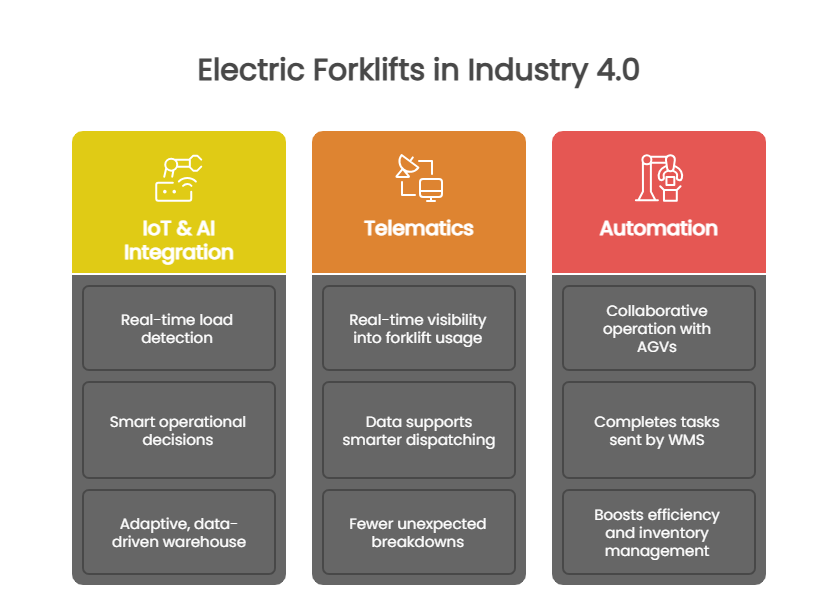

Electric Forklifts as a Catalyst for Industry 4.0 Transformation

Electric forklifts are no longer just clean machines—they’re becoming intelligent, connected assets at the core of modern material handling systems. Their compatibility with Industry 4.0 technologies is accelerating digital transformation across warehouses and factories.

Integration with IoT and AI

Today’s electric forklifts are no longer just machines that move pallets. They are becoming intelligent, connected tools on the warehouse floor. With built-in IoT sensors, edge computing, and cloud connectivity, they can detect loads in real time, sense obstacles, and adjust their routes dynamically.

When combined with AI and machine learning, they are capable of making smart operational decisions such as avoiding collisions, controlling speed, and optimizing pick-up and drop-off tasks.

Instead of simply following commands, these battery-operated forklifts actively respond to their environment and contribute to a more adaptive, data-driven warehouse system.

Fleet Telematics and Predictive Maintenance

Telematics systems give managers real-time visibility into forklift usage, battery status, and operator activity across the entire fleet. This data supports smarter dispatching, more accurate maintenance planning, and fewer unexpected breakdowns.

Automation-Ready for Smart Warehouses

Electric forklifts aren’t just working on their own anymore—they’re part of a bigger, smarter system. They team up with AGVs, robots, and automated palletizers to keep things moving smoothly from start to finish.

Take AGV forklifts, for example. In many automated warehouses, especially in e-commerce and manufacturing, these driverless vehicles handle everything from moving pallets between workshops and storage to completing tasks sent automatically by the warehouse management system (WMS). This means less manual work, fewer delays, and way faster operations. Ultimately, warehouse automation boosts efficiency and makes managing inventory and space easier.

Is Your Fleet Ready for the Future?

Investing in electric forklifts isn’t just about keeping up with trends—it’s a long-term move that pays off on multiple levels. While the upfront cost may be higher than internal combustion models, lower energy bills, reduced maintenance needs, and fewer regulatory hurdles lead to significant savings over time.

On the sustainability front, electric fleets help businesses hit emissions targets and stay ahead of tightening environmental rules. And with the rise of smart warehouses and automated workflows, electric models offer the flexibility and connectivity that today’s operations demand. In short, going electric is a sustainable move that also sets your operations up for smarter, more efficient performance.

To get the most out of your investment, it’s important to choose models that match your specific operating conditions.

Light-load, high-speed operations

In fast-moving industries like e-commerce fulfillment and retail logistics, speed and uptime are everything. These operations benefit most from compact electric forklifts equipped with lithium-ion batteries, which charge faster and support continuous use. Models like AGVs with automation-ready features can also integrate easily with warehouse robots and inventory systems, ideal for facilities running 24/7.

Heavy-duty or complex environments

Manufacturing plants, ports, and construction sites demand tougher machines that can handle high loads, long shifts, and harsh conditions. High-capacity electric forklifts with reinforced frames, thermal management systems, and robust telemetry are better suited for these environments. They ensure reliable performance while still meeting sustainability goals, even under heavy strain.

Conclusion

So, are electric forklifts good? Sure. Electric forklifts are now reshaping the future of material handling by combining environmental responsibility with smarter performance. They reduce emissions, cut operating costs, and integrate easily into connected, automated workflows.

As more industries push for cleaner and more agile supply chains, electric fleets are becoming a practical and forward-thinking choice.

HELI, ranked among the top 7 global forklift manufacturers, offers a wide range of electric forklift solutions designed to help businesses stay competitive, both now and in the years ahead. Take the first step toward a smarter, greener fleet. Why wait?

References

- Forklift Trucks Market Hit Valuation of US$ 102.87 Billion by 2033 | Astute Analytica. Available at: https://www.globenewswire.com/news-release/2025/05/07/3076314/0/en/Forklift-Trucks-Market-Hit-Valuation-of-US-102-87-Billion-by-2033-Astute-Analytica.html(Accessed on July 8, 2025)

- Electric Forklifts Market. Available at: https://www.fairfieldmarketresearch.com/report/electric-forklifts-market(Accessed on July 8, 2025)

- Zero-Emission Forklifts. Available at: https://ww2.arb.ca.gov/our-work/programs/zero-emission-forklifts(Accessed on July 8, 2025)