When to Choose a Telescopic Handler Over Other Industrial Forklifts

Forklifts may look similar at first glance, but choosing the wrong one can quickly turn into a logistical nightmare. The right machine doesn’t just lift—it solves problems before they happen.

Among the many options, telescopic handlers, or telehandlers, stand out for their versatility. With the ability to extend and retract their boom, they handle tasks that go beyond the reach of conventional forklifts, especially on uneven or demanding job sites.

But that raises an important question: when does it actually make sense to choose a telescopic handler over other industrial forklifts?

What is a Telescopic Handler?

A telescopic handler, often called a telehandler, is one of the most versatile pieces of equipment you’ll find on a jobsite. Think of it as a hybrid between a forklift and a crane: it combines the lifting ability of the former with the extended reach of the latter.

This unique design makes it indispensable across industries like construction, agriculture, and even event setup—anywhere loads need to be lifted, moved, or placed with precision.

Key features of telescopic handlers:

- Telescopic Boom Arm:Unlike standard forklifts that lift straight up, a telehandler’s extendable boom can reach upward, outward, and even at an angle—sometimes up to 50+ feet.

- Versatility with Attachments: From pallet forks to buckets, truss booms, and work platforms, the machine can adapt to countless tasks.

- Rough-Terrain Performance:Built with stability features and often equipped with outriggers, telescopic handlers handle uneven outdoor surfaces with ease.

- Safety and Load Management:Modern models include load charts and sensor systems to prevent tipping and ensure safe operations, even at extended reaches.

In short, a forklift telehandler is the “Swiss Army knife” of forklifts—compact enough for tight sites, yet powerful and adaptable enough to replace multiple machines.

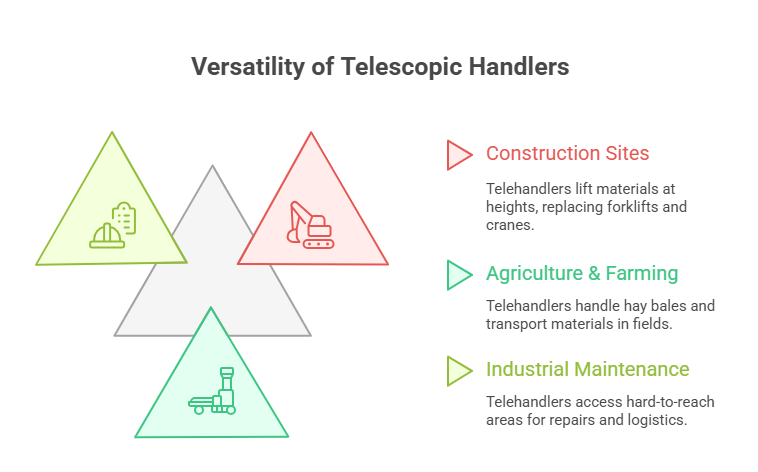

Key Scenarios Where Telescopic Handlers Excel

Telehandlers aren’t just versatile on paper—their true value shines in real-world applications. With their extended reach, rough-terrain performance, and wide range of attachments, they can often replace multiple machines on a jobsite. Here are the situations where a telescopic handler proves to be the smarter choice:

Construction Sites

Telehandlers are indispensable on construction projects where materials need to be lifted and placed quickly at different heights. They can carry bricks, steel beams, or prefabricated panels across uneven ground and deliver them to upper floors—tasks that would otherwise require both a forklift and a crane. By reducing equipment needs, they save time, space, and rental costs.

Agriculture & Farming

On farms, one machine that can do it all is a game-changer. Telehandlers handle everything from stacking hay bales to transporting feed and fertilizer, even in muddy or uneven fields. Switching from forks to a bucket or grab takes only minutes, letting farmers move seamlessly between tasks without bringing in multiple tractors or loaders.

Industrial Maintenance & Outdoor Logistics

When it comes to accessing hard-to-reach areas or moving heavy loads outdoors, telehandlers deliver unmatched flexibility. With a work platform attachment, they can safely lift workers for roof repairs, façade maintenance, or utility installation. They’re also highly effective for outdoor logistics—unloading trucks, clearing debris, or moving materials across large sites where traditional forklifts would struggle.

Comparing Telescopic Handlers with Other Industrial Forklifts

Feature | Telescopic Handler | Rough-Terrain Forklift | Standard Counterbalance Forklift |

Lift Capacity | High, but decreases as boom extends (5,000 lb retracted may drop to <500 lb fully extended) | Moderate; maintains capacity but limited reach | Moderate; consistent vertical lift for palletized goods |

Working Height | Up to 30–50+ ft | Limited; generally under 20 ft | Low; designed for stacking a few pallets high indoors |

Horizontal Reach | Excellent Extend boom forward and over obstacles | Minimal – lifts only straight up | None – vertical lift only |

Attachments | Wide range: forks, buckets, grabs, platforms, truss booms, winches | Basic forks, limited attachment options | Mostly forks; some clamp or specialized attachments |

Maneuverability | Larger footprint; best for outdoor sites, rough terrain, uneven ground | Good on outdoor terrain, but less flexible than telehandlers | Compact, excellent for tight indoor aisles |

Summary:

- Telescopic handlers shinewhen projects demand reach, versatility, and adaptability across uneven ground.

- Rough-terrain forklifts are a simpler outdoor option, effective where stability is needed but extended reach isn’t.

- Standard counterbalance forklifts remain the go-to choice indoors, especially in warehouses where space is tight.

In short: if your jobsite requires height, reach, and multi-functionality, the telescopic handler is the smarter investment.

Benefits of Choosing a Telescopic Handler

For jobs that push limits, telescopic handlers provide the reach, power, and flexibility to get the work done right.

- Multi-functionality & Operational Flexibility: Quick-change attachments let a rough terrain telehandler perform the tasks of a forklift, crane, and loader in one machine.

- Increased Efficiency & Cost Savings: Telehandlers streamline workflows by handling multiple tasks on one machine and placing materials precisely, saving time, labor, and equipment costs.

- Enhanced Safety: Stabilizers and load monitoring systems (like LSI) keep operations secure at height or on uneven terrain.

- Adaptability to Challenging Environments: Telehandlers navigate rough or uneven terrain with stabilizers and extendable booms, allowing precise load placement over obstacles that standard forklifts can’t reach.

Factors to Consider Before Making the Choice

Before picking a telehandler, consider how your environment, tasks, and costs will impact its performance and value.

- Site Type: Consider whether your workspace is narrow or open, indoor or outdoor. Rotating telehandlers excel in confined spaces, while standard models perform well in open areas.

- Load Capacity & Lift Height: Determine the maximum weight, reach, and lift height required. Remember that lifting capacity decreases as the boom extends.

- Task Type & Frequency: Assess whether the telehandler will handle short-term lifting tasks or serve as a multi-purpose machine for ongoing operations.

- Budget, Maintenance & Support: Factor in purchase vs. rental costs, ongoing maintenance, fuel, and the availability of after-sales service to ensure long-term reliability.

HELI Telescopic Handlers

If your project involves uneven terrain, tight spaces, or heavy lifting, investing in a reliable telescopic handler ensures your project stays on track. HELI, a trusted name in material handling, delivers machines designed to meet these challenges.

The HELI 3–5t Telescopic Handlers, part of this lineup, glide over uneven terrain and tight spaces thanks to a four-wheel drive and three steering modes. They ensure precise handling with the intelligent control handle and automatic fork leveling, and maintain safety on every lift through real-time load monitoring. With these features, moving, stacking, or placing materials becomes faster, smoother, and worry-free.

Conclusion

Telescopic handlers transform challenging jobs into manageable tasks, offering reach, versatility, and precision that standard forklifts can’t match. From navigating rough terrain to lifting heavy loads safely and efficiently, they’re built to keep your projects moving.

Ready to see how a telehandler can simplify your workflow? Explore the HELI 3–5t Telescopic Handlers today and take your material handling to the next level.