Material Handling Made Safer with the Right Forklift Types

Forklift trucks, as the core equipment of logistics and warehousing, can efficiently complete the tasks of material handling, stacking, loading, and unloading.

Choosing the right type of forklift is crucial to improving operational efficiency and safety, so this article will analyze the characteristics of different types of forklifts and applicable scenarios, helping you to select the right type and optimize the material handling process.

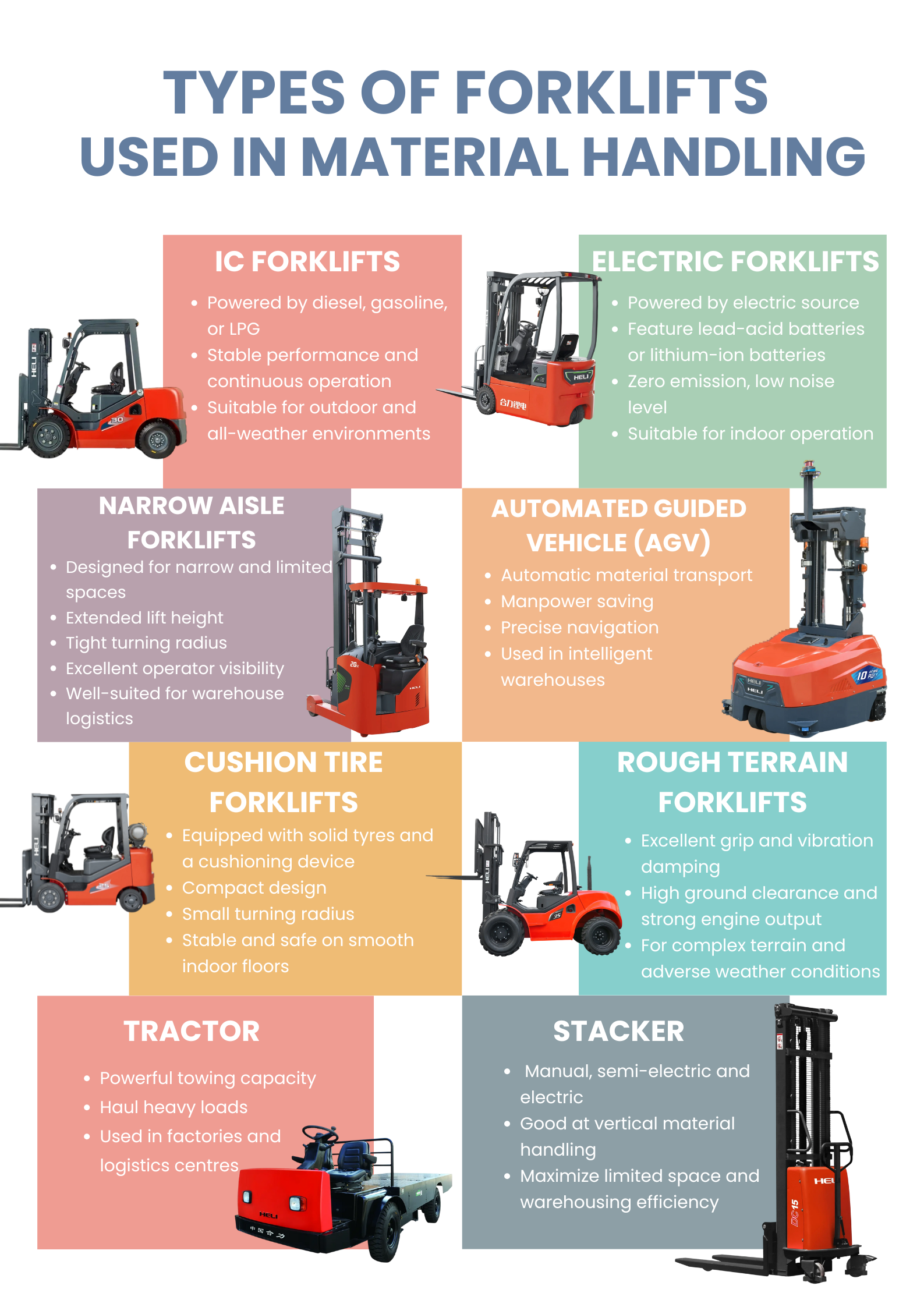

Internal Combustion (IC) Forklifts

Internal combustion (IC) forklifts are powered by fuels such as diesel, gasoline, or liquefied petroleum gas. Driven by internal combustion engines, IC forklifts deliver strong power out and extended operating time.

Besides, they feature stable performance and adapt to outdoor and all-weather environments. With their long range and high payload capacity, they are well-suited for demanding and complex working conditions in logistics, construction, and harbor scenarios.

Despite continuous operation beneficial in remote locations, IC forklifts require proper ventilation and adherence to fuel storage regulations.

Electric Forklifts & Li-ion Forklifts

Among all types of forklifts available, electric forklifts are characterized by their electric power source. They operate by turning electrical energy into mechanical energy through an electric motor, which drives both the travel and lifting functions of the truck.

Traditionally, most electric forklifts have used lead-acid batteries due to their mature technology and low cost. However, these batteries come with drawbacks such as large size, long charging times, and limited lifespan.

In recent years, lithium-ion forklifts have emerged as a preferred alternative. With faster charging capabilities, higher energy density, and longer service life, lithium-ion batteries give electric forklifts a clear edge in demanding work environments.

Due to their zero emissions and lower noise levels, electric forklifts are commonly found in indoor operations in warehouses, supermarkets, and other manufacturing facilities.

Narrow Aisle Forklifts

Specifically designed for narrow and limited spaces in high-density storage environments, narrow aisle forklifts include reach trucks and order pickers.

Their extended lift height enables access to upper-level racks, tight turning radius allows for smooth navigation through narrow aisles, and excellent operator visibility guarantees safe and efficient operations.

Thanks to these features, narrow aisle forklifts have become a typical choice in optimizing vertical storage in warehouse logistics.

Automated Guided Vehicle (AGV)

AGV (Automated Guided Vehicle) is a robotic forklift designed for automatic material transport. It achieves unmanned handling by navigating through pre-set paths or sensors.

AGV forklifts feature manpower saving to reduce operation costs, precise navigation to ensure accurate material transport, and 24-hour uninterrupted operation to enhance productivity.

As a modern alternative to traditional warehouse forklift types, AGVs take care of material handling and storage with speed and precision in intelligent warehouses. Furthermore, in lean manufacturing, they help smooth out logistics, cut down on disruptions, and contribute to smarter operations.

Cushion Tire Forklifts

A cushion tire forklift truck is a forklift equipped with solid tires and a cushioning device. With a compact and short body and a small turning radius, it has the flexibility to maneuver in tight spaces and can easily cope with narrow aisles and tightly stacked environments.

Equipped with solid tires that don’t need inflation, it stays stable and safe on smooth indoor floors like those in warehouses or loading docks — avoiding risks from tire leaks or uneven ground and making it a smart choice for indoor use.

Rough Terrain Forklifts

Rough terrain forklifts are a specialized type of forklift designed for demanding outdoor environments and challenging ground conditions.

Equipped with large pneumatic tires, this forklift model delivers excellent grip and vibration damping. Compared with other different types of forklifts, they offer better adaptability to uneven surfaces thanks to their high ground clearance and strong engine output for outdoor use.

Therefore, rough terrain forklifts are particularly suitable for operation in complex terrain and adverse weather conditions, making it a preferred choice for construction, agriculture and other industries.

Tractors

Industrial tractors are used in factories and logistics centres for hauling heavy loads, with powerful towing capacity and efficient operating performance.

As one of the different types of forklifts, they can tow various types of trailers or hitches, providing a high degree of operational versatility and flexibility in responding to different cargo transport needs.

In airport ground operations, industrial tractors can be used to tow aircraft trailers and baggage trailers; in warehouses, they tow pallet trucks to achieve rapid handling and transfer of goods, which is an indispensable piece of equipment in logistics transport.

Stackers

Stackers are a type of equipment used for material handling and storage and are generally divided into three types: manual, semi-electric, and electric.

- Manual stackers are simple to use, low-cost, and suitable for light loads and low-frequency operations;

- Semi-electric stackers are electrically driven to lift and lower the intensity of operation and are suitable for medium loads;

- Electric stackers are fully electrified, easy to operate, and highly efficient, and are ideal for frequent operations.

They are used for stacking and handling goods in small-scale warehousing and are especially good at vertical material handling, maximizing limited space and warehousing efficiency.

Partner with HELI for Complete Forklift Solutions

Understanding the different types of forklifts is only the first step—what truly drives long-term success is choosing the right partner behind the machine. Beyond equipment, it’s the expertise, support, and reliability of your forklift provider that powers lasting performance.

For businesses seeking more than just a machine, HELI delivers complete forklift solutions backed by proven performance. As one of the world’s top 10 forklift manufacturers, HELI offers a wide portfolio of forklifts, ranging from internal combustion models and li-ion forklifts to automated guided vehicles (AGVs).

With decades of engineering expertise and global reach, HELI supports material handling operations across a wide spectrum of industries, including automotive manufacturing, chemical processing, cold chain logistics, warehousing, and intelligent supply chains.

Ready to elevate your material handling operations? Partner with HELI and experience the difference of tailored forklift solutions built for performance.

FAQ

1. What are the main types of forklifts?

The most common forklift types include internal combustion forklifts, electric forklifts, narrow aisle forklifts, AGVs, cushion tire forklifts, rough terrain forklifts, tractors, and stackers. Each type has specific strengths for different environments and applications.

2. Which forklift is best for indoor warehouses?

Electric forklifts and cushion tire forklifts are ideal for indoor use. They produce zero emissions, operate quietly, and maneuver easily in tight spaces.

3. What forklift is suitable for outdoor or rough terrain?

For construction sites, farms, and uneven ground, rough terrain forklifts with pneumatic tires and strong engines offer the best performance.

4. Are lithium-ion forklifts better than lead-acid forklifts?

Yes. Lithium-ion forklifts charge faster, last longer, and require less maintenance compared to lead-acid battery forklifts, making them more efficient for high-intensity operations.

5. Why choose HELI for forklift solutions?

HELI is one of the world’s top 10 forklift manufacturers, offering a full range of forklifts from IC to lithium-ion to AGVs, backed by strong engineering expertise and reliable global support.