Forklift Battery Types Compared: Lead-Acid or Lithium-Ion?

Every minute a forklift sits idle due to a dead or slow-charging battery costs your operation money. In high-volume warehouses, the wrong battery choice can mean hours of lost productivity each week and thousands in extra operating costs each year.

That’s why choosing the right forklift battery type is critical. Today, the two main options, lead-acid and lithium-ion, offer very different trade-offs. The question is: Which one will keep your operation running at peak efficiency?

Overview of Forklift Battery Types

What type of battery does a forklift use? The answer usually comes down to lead-acid or lithium-ion batteries. Each type has distinct components and operating principles that affect performance, maintenance, and suitability for different applications.

1. Lead-Acid Forklift Batteries

Lead-acid batteries have been the industry standard for decades. They store energy through a chemical reaction between lead plates and sulfuric acid. The main components include the positive and negative lead plates, separators, electrolyte solution, and a durable outer casing. When discharging, a chemical reaction releases electrical energy to power the forklift; during charging, the reaction is reversed to restore energy.

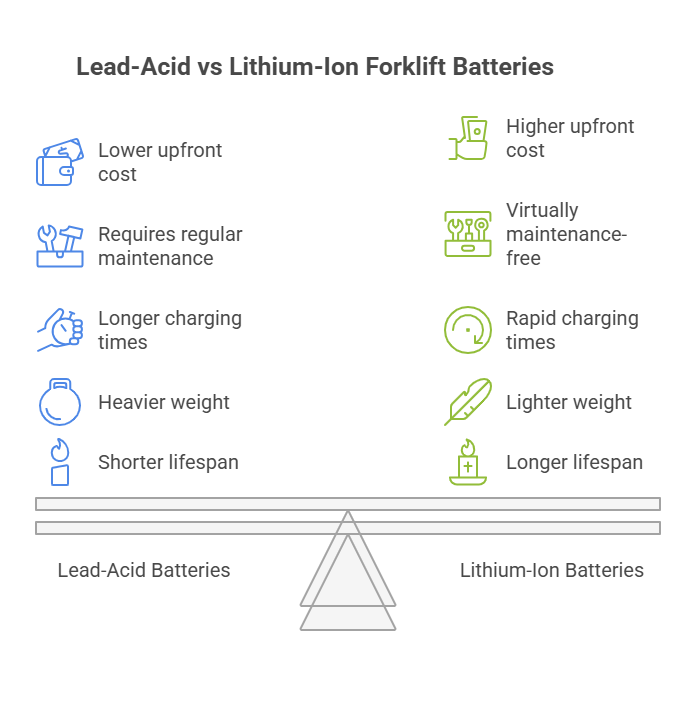

Key Features:

- Proven, mature technology with a lower upfront cost.

- Requires regular maintenance, including watering and equalizing charges.

- Longer charging times, typically around 8 hours plus additional cooling time.

- Heavier weight, which can aid forklift counterbalancing.

2. Lithium-Ion Forklift Batteries

Lithium-ion batteries use lithium compounds as the active material and store energy through the movement of lithium ions between the anode and cathode via an electrolyte. Components typically include lithium cells, a battery management system (BMS), and a protective casing. The BMS plays an important role in monitoring voltage, temperature, and charge cycles, enhancing safety and performance.

Key Features:

- Higher energy density for longer runtime per charge.

- Rapid charging, often reaching full capacity in 1-2 hours.

- Virtually maintenance-free with no need for watering.

- Longer lifespan, typically 2–3 times that of lead-acid.

Key Differences between Lead-Acid and Lithium-Ion Forklift Battery

Aspect | Lead-Acid | Lithium-Ion |

Initial Cost | $2,000-$6,000 per battery[1] | $17,000-$25,000 per battery[1] |

Lifespan | 1000-1,500 charge cycles (≈ 3-5 years)[2] | 2,000-3,000 charge cycles (≈ 7–10 years) [2] |

Charging Time | 8-10 charging hours + 6-8 hours cooling[2] | 1-2 hours, no cooling needed[2] |

Maintenance | High Need watering every 5-10 cycles[3], cleaning, and equalizing | Minimal no watering, no cleaning, sealed unit |

Energy Efficiency | ~80% charging efficiency[2] | ~99% charging efficiency[2] |

Multi-Shift Capability | Needs 2-3 batteries per forklift[2] | 1 battery per forklift with opportunity charging[2] |

Recycling | Recyclable with an established infrastructure | More complex recycling process |

Safety | Sulfuric acid risk, hydrogen gas emissions, heavy handling | Sealed unit, no acid exposure, no toxic gas emissions |

Environmental Impact | Hazardous material disposal risks if improperly recycled | Zero emissions during operation, reduced carbon footprint |

ROI Timeline | Lower initial cost advantage | Break-even within 36 months for multi-shift ops[1] |

Total Cost of Ownership (TCO) | Higher due to frequent replacements, maintenance, and multiple batteries needed for multi-shift | Lower due to longer lifespan, minimal maintenance, and single battery use for multi-shift operations |

Lead-acid forklift batteries remain attractive for operations with tight capital budgets, single-shift schedules, and in-house maintenance capabilities. They offer a much lower upfront cost and benefit from a mature recycling infrastructure.

However, lithium-ion forklift batteries outperform in multi-shift operations, high-throughput warehouses, and businesses aiming for lower total cost of ownership. Faster charging, higher energy efficiency, longer lifespan, and reduced maintenance often deliver ROI in under three years, making them a strategic choice for companies prioritizing productivity, safety, and sustainability.

Which Battery-Powered Forklift Suits Your Needs?

When selecting a forklift battery type, it’s essential to align your choice with your operation’s scale, shift frequency, budget, and maintenance capabilities. Here are some recommendations based on different business needs:

1. Small Fleets with Single-Shift Operations

If your business operates with a small fleet and runs on a single shift, lead-acid batteries could be a good fit. These situations prioritize lower upfront costs and can afford the longer charging times of lead-acid systems.

When to choose lead-acid:

- Limited budget for initial investment.

- Overnight charging is acceptable.

- Sufficient maintenance resources available for routine checks (watering, cleaning, equalizing).

- Environmental controls in place to handle charging and gas emissions.

Example:

A small warehouse with 5 forklifts operating during the day can use lead-acid batteries. As long as they have overnight charging and the resources to manage the batteries, lead-acid can be a cost-effective solution, especially if the operation doesn’t require 24/7 uptime.

2. Large Fleets or Multi-Shift Operations

For businesses operating with large fleets or running multi-shift operations, lithium-ion batteries are often the better choice. These batteries support continuous operation, reducing downtime and minimizing the need for extra batteries.

When to choose lithium-ion:

- Continuous operations with minimal downtime.

- Opportunity charging during breaks or idle time is possible.

- Lower maintenance requirements, with no need for watering or equalizing.

- Enhanced safety protocols are a priority (e.g., reduced risk of toxic gas exposure and less handling required).

Example:

A large logistics center operating 24/7 with 50 forklifts would greatly benefit from lithium-ion batteries. With single-battery use per forklift, they can take advantage of rapid charging during breaks, leading to reduced downtime and improved productivity.

3. Considerations for Financial Position and Maintenance Capacity

Budget-conscious businesses may find lead-acid batteries appealing due to their lower initial costs, but they should carefully assess the total cost of ownership (TCO) over the long term.

Businesses with limited maintenance capacity might opt for lithium-ion forklift batteries as they are virtually maintenance-free, which can reduce operational complexity.

Power Your Fleet with Reliable Electric Forklifts from HELI

As a leading global manufacturer of industrial trucks, HELI is committed to delivering high-quality electric forklifts to meet the demands of modern warehouses and supply chains.

Energy Efficiency and Sustainability

HELI battery-powered forklifts are designed to minimize power consumption, delivering high efficiency and low operating costs. Their advanced battery technology ensures a reduced carbon footprint, aligning with sustainability goals without compromising on performance.

Versatile Industry Solutions

HELI offers customized forklift solutions for a wide range of industries, including intelligent logistics, automotive, chemical, cold chain, foundry, home appliances, furnishings, and photovoltaics. Whether you need forklifts for heavy-duty tasks or sensitive goods handling, HELI has the ideal solution to optimize your operations.

Ergonomic Design for Operator Comfort

The comfort and safety of your operators are top priorities. HELI electric forklifts feature ergonomic designs, providing comfortable seating and intuitive controls to reduce fatigue and enhance productivity throughout long hours of operation.

Global Support and Expertise

With a global presence and a strong network of service centers, HELI provides exceptional after-sales support, ensuring your fleet operates smoothly for years to come. From spare parts availability to expert technical support, HELI is always by your side.

Conclusion

There’s no one-size-fits-all answer for choosing forklift battery types. Lead-acid offers lower upfront costs and proven reliability for single-shift or low-intensity operations, while lithium-ion excels in multi-shift environments with faster charging, longer lifespan, and minimal maintenance. The best choice depends on your operation scale, shift patterns, and budget priorities.

Not sure which is right for you? HELI can help you assess your needs and recommend the optimal battery and forklift solution to keep your fleet running at peak performance. Contact us today to power your business forward.

References

[1]. 2024 How Much Does a Forklift Battery Cost. Available at: https://manlybattery.com/how-much-does-a-forklift-battery-cost/.(Accessed on August 11, 2025)

[2]. Lithium Forklift Batteries: The Complete Guide [Pros, Cons, Costs]. Available at: https://www.conger.com/lithium-forklift-battery/.(Accessed on August 11, 2025)

[3]. Watering Forklift Batteries: The Complete Guide for Battery Room Operators. Available at: https://na.bhs1.com/blog/post/watering-forklift-batteries-the-complete-guide-for-battery-room-operators.(Accessed on August 11, 2025)